Resources

Manufacturing in Wisconsin

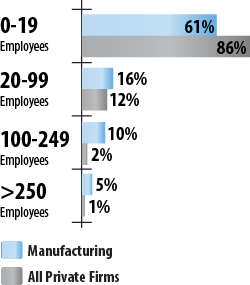

As with the U.S. economy as a whole, Wisconsin’s economy has undergone a fundamental shift over the last fifty years from a manufacturing to a service economy. In 1961, for example, about 39% of Wisconsin’s non-farm workforce was employed in manufacturing. In 2011, this figure had fallen to about 16% of the state’s non-farm workforce. The comparable shift at the national level, however, has been much greater, with manufacturing accounting for only about 8 to 9% of total employment in the U.S. non-farm workforce in 2011. As a result, Wisconsin typically has the highest percentage of employment in manufacturing activities of any state in the nation.

Not surprisingly, Wisconsin also ranks in the top five states in terms of the share of the state’s gross domestic product attributable to manufacturing. The economy of Wisconsin is nearly a quarter of a trillion dollars with manufacturing accounting for one-fifth of the state’s total economic output. In 2008, the last year for which the data have been released, manufacturing contributed $48.9 billion in economic output.

With an average annual manufacturing wage of more than $48,100 and a $23.7 billion annual manufacturing payroll in Wisconsin in 2009, manufacturing firms continue to play an important role in the state’s economy. Creating an enhanced, next-generation manufacturing capacity requires a highly skilled and motivated workforce that will both attract new firms and enable existing manufacturing-related firms and sectors—such as transportation, logistics, and scientific research—to grow.

As with most state’s, Wisconsin’s workforce is aging, creating a growing need for replacement workers. In manufacturing, as firms embrace new technology and ways of organizing the workplace, these new workers typically need to be more highly skilled than those they are replacing. As a recent report on trends in manufacturing staff indicated, the manufacturing workplace of the future will have “Fewer employees on more teams, using more technology to make crucial decisions more quickly.” The skills manufacturers say they will need in this new environment include: broad mechanical reasoning, logic, troubleshooting and spatial visualization; personal flexibility, communication, and cooperation; initiative, persistence, and independence; attention to detail, self-control, and dependability; independent decision making; and using computers to operate machinery and perform a wide range of critical functions. Learn more about the fundamental shift in manufacturing skills (PDF).

One sign of this shift to greater skill needs is the growing importance of middle skill jobs in manufacturing. Middle skill jobs are those requiring some education or training beyond high school. The Wisconsin Department of Workforce Development estimates that between 2008 and 2018, 3 out of every 4 openings in manufacturing-related occupations in Wisconsin will be middle skill jobs. These middle skill jobs are typically for manufacturing engineering technologists or technicians and skilled craft persons. Wisconsin’s technical colleges are the primary provider of education and training for both types of jobs. Learn more about the occupational programs available at Wisconsin’s technical colleges and manufacturing in Wisconsin and the state’s manufacturing workforce (PPT).